1. The Source Of Petroleum Coke

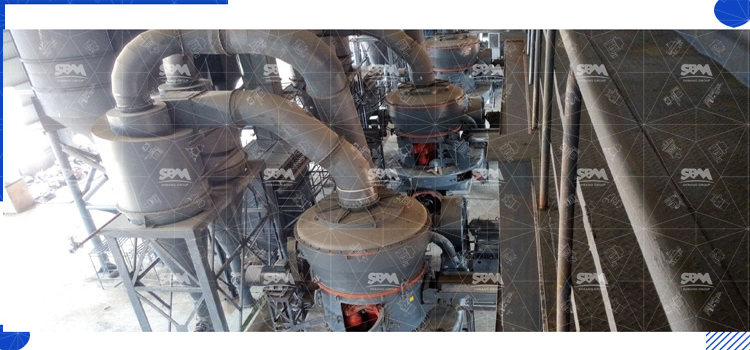

The mill manufacturer SBM recommends that customers use professional petroleum coke grinding equipment. The production of 200 mesh particles of calcined petroleum coke powder can not only reduce energy consumption, realize environmentally friendly and energy-saving production, but also has good powder quality.

Petroleum coke is the "waste" at the end of the petroleum refining process, so the technology of replacing heavy oil with 100 mesh particles of calcined petroleum coke powder is ["petroleum coke powder instead of heavy oil technology"] a typical circular economy, and it is also a good new energy application. At the same time, it also responded to the call of the country for environmental protection. Petroleum coke mill, petroleum coke processing equipment, petroleum coke powder, petroleum coke processing technology SBM advanced technology.

Petroleum coke mill, petroleum coke processing equipment, petroleum coke powder, calcined petroleum coke powder 100 mesh granular petroleum coke processing process

2. The Processing Process Of 200 Mesh Petroleum Coke European Version Mill Is As Follows

1. Crushing Stage: The large piece of petroleum coke is crushed by the crusher to the fineness of feed (15mm-50mm) into the petroleum coke pulverizing equipment.

2. Grinding Stage: Small pieces of petroleum coke particles that meet the conditions for entering the mill are uniformly and quantitatively fed into the main engine of the 200 mesh petroleum coke European version mill through the conveying and feeding system for grinding, classification, and packaging.

Engineer one-to-one for you, draw up plans in time, and provide investment estimates in time!

Maybe You're Interested

MTW110 Trapezium Mill For Activated Carbon Production Line

Vertical Roller Mill For Chinese Medicine Industry

The Reason Why The Mill Is Noisy When It Is Working