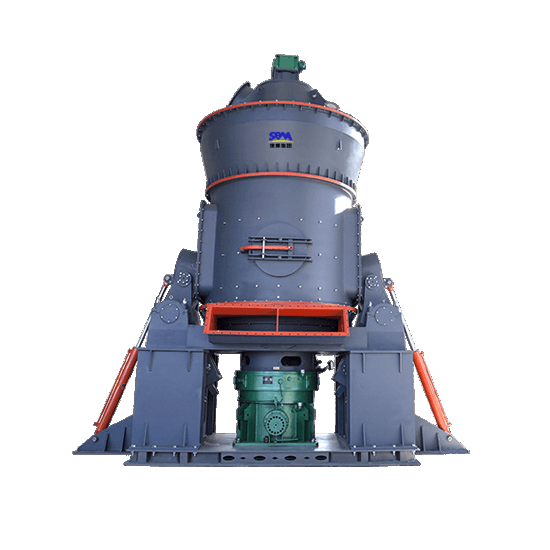

Main Structure

LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing. Separtor is a kind of efficient and energy-saving powder concentrator. The roller is a component which is used for crushing the materials. Turntable is fixed on the output shaft of the speed reducer where the materials are crushed. Pressure device is a component which is used for providing the roller with enough crushing pressure to crushing materials.

.jpg)

.jpg)

.jpg)

.jpg)