SBM has developed new trapezium mill to meet the increasing demand for automation and process control. The development work is based on comprehensive experience.

Traditional Raymond mill generally has a fineness below 500 mesh, which can only be applied to some low-end production occasions, and the production technology is backward, continuous failures, and high power consumption.

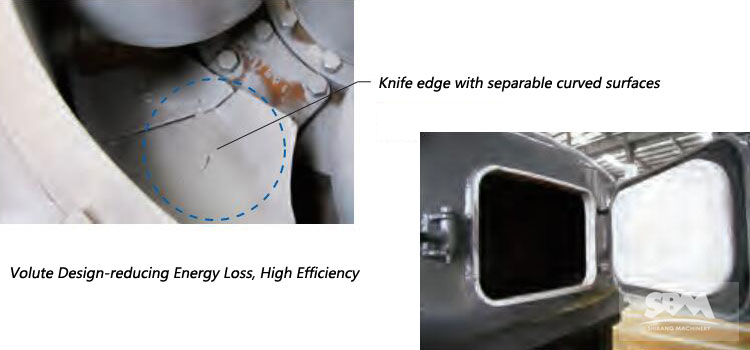

Volute Design-reducing Energy Loss, High Efficiency

The inner face of inner door sheet is on the same curved surface as inner face of air intake volute, can effectively avoid eddying effect and reduce energy loss. It's reported that it can integrally save more than 20% energy.

Arc Air Duct Design-reducing Resistance

The tangential airflow inlet is smooth with small resistance. The inner outlet direction is favorable to dispersal of materials and note easy to plug.

Engineer one-to-one for you, draw up plans in time, and provide investment estimates in time!

Maybe You're Interested

The Use Of Calcined Petroleum Coke Powder

Raymond Mill Future Development